Rotary transmission systems put two rotating elements into contact. These mechanisms have two purposes:

⇒Transferring rotary force to an input location to another location.

⇒Changing the rotary speed by using rotating elements of different sizes.

There are various mechanisms:

|

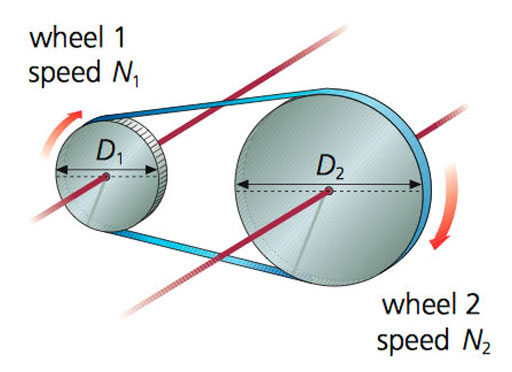

| Pulleys with belts |

|

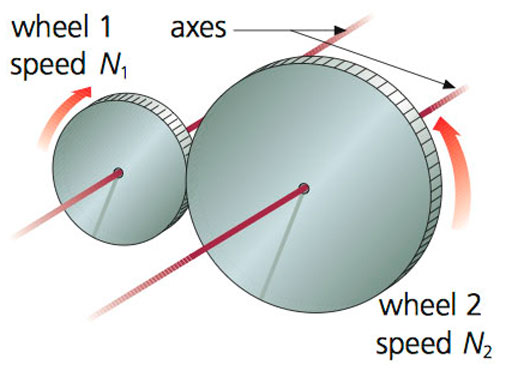

| Friction wheels |

|

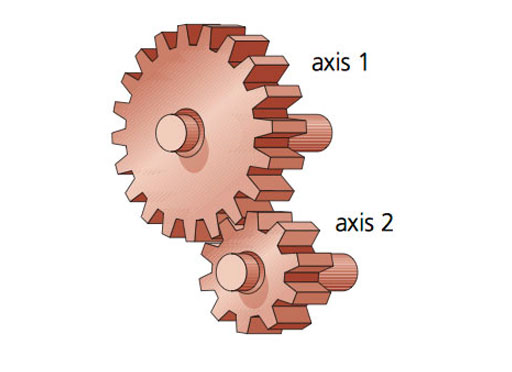

| Interlocking gears |

|

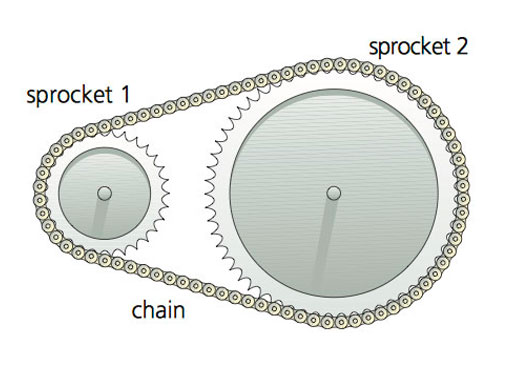

| Sprockets with chains |

Here, the most reliable mechanism is the interlocking gears, because they don't slip easily.

CHANGES IN SPEED

We can increase, decrease and make constant the speed with these systems:

|

| Decreasing and Increasing speed system |

|

| Cosntant speed system |

SPEED RATIOS

The relationship between the speeds of the two wheels is inversely proportional to their sizes.

N2/N1=D1/D2

The relationship is called the ratio of transmission, where N is the speed of relation and D is the diameter of the wheel.

BELT DRIVES AND GEAR TRAINS

We can change the direction of the rotation by using belts in different possicions or different axis.

WORM DRIVE

A worm drive reduces the speed of rotary system very well. It has two parts: a worm shaft and a worm gear. The shaft has more than one groove. Each groove interlocks with one of the worm gear. This mechanism is not reversible.

BELT DRIVES AND GEAR TRAINS

-Wheel 1 turns wheel 2, wich moves faster because it is smaller. If wheel 1 makes 1 rotation, wheel 2 makes 1.5 rotations.

-Wheel 2 and wheel 3 are connected to the same axis, so they turn together.

-Wheel 3 turns wheel 4, wich moves faster because it is smaller. If wheel 3 makes 1.5 rotations, wheel 4 makes 3 rotations (1.5x2=3)

N4/N1=D1XD3/D2XD4

CHANGES IN DIRECTION AND ROTATIONS

|

| Parallel axes |

| Perpendicular axes |

| Different posicion of the belts |

|

| Crossed axes |

WORM DRIVE

A worm drive reduces the speed of rotary system very well. It has two parts: a worm shaft and a worm gear. The shaft has more than one groove. Each groove interlocks with one of the worm gear. This mechanism is not reversible.

No hay comentarios:

Publicar un comentario